Introduction: Why Speed Detection Matters in Industry

In modern factories and logistics systems, understanding how fast objects are moving is no longer optional—it is essential. Whether tracking conveyor belt velocity, monitoring automated guided vehicles (AGVs), or measuring rotating machinery, speed detection forms the basis of safety, efficiency, and automation.

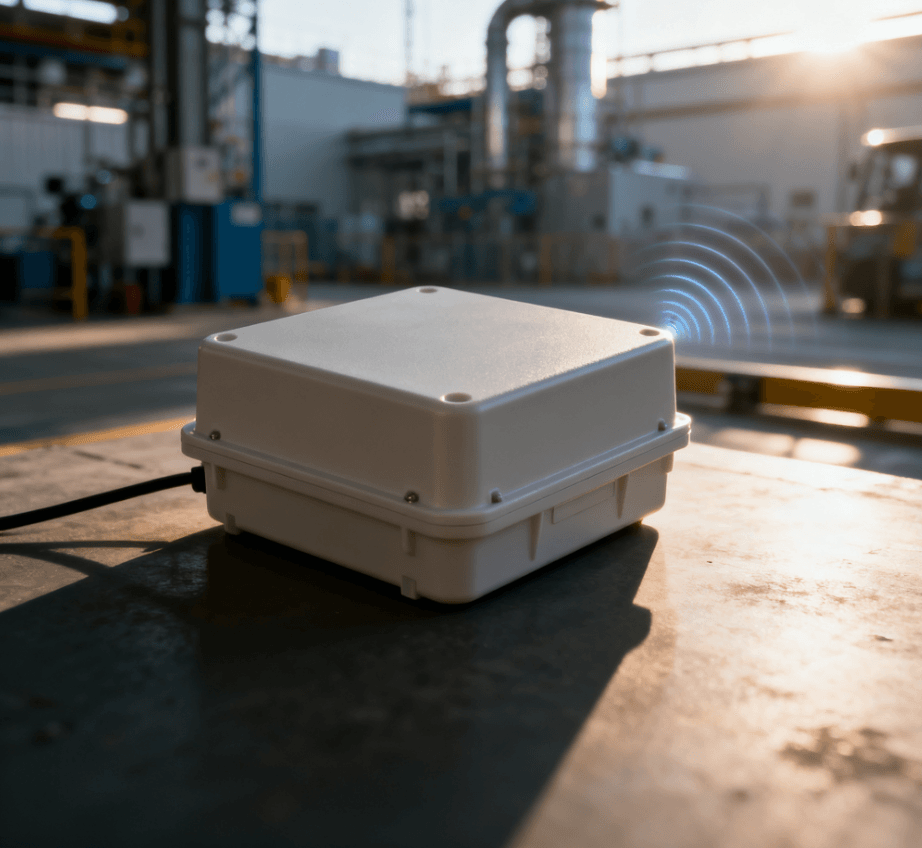

Traditional methods such as optical encoders or camera-based systems often struggle in industrial environments filled with dust, smoke, or poor lighting. Mechanical sensors, on the other hand, suffer from wear and require frequent maintenance. This is why mmWave radar sensors are increasingly being deployed. They provide non-contact, real-time, and weather-agnostic velocity measurements that remain reliable even under harsh conditions.

At Linpowave, we see industrial customers moving away from fragile legacy solutions toward radar-based detection, particularly for scenarios where downtime is costly. But how does mmWave radar actually measure speed, and what challenges must be solved to ensure accuracy?

The Principles Behind Radar Speed Detection

The Doppler Effect at Work

The foundation of radar speed detection is the Doppler effect. When a target moves relative to the radar, the frequency of the reflected signal shifts proportionally to its velocity. This shift allows the radar to calculate radial velocity—the component of speed directly toward or away from the sensor.

This principle is the same as the one used in police radar guns, but industrial radar modules have evolved significantly. Compact 24 GHz and 60 GHz sensors now integrate transmitters, receivers, and signal processing into a single chip, enabling precise velocity measurements in factory settings (Infineon Radar Sensors).

Why Radial Velocity Matters

Radar measures only the radial component of velocity. For example, if a conveyor moves perpendicularly to the sensor’s line of sight, the measured speed may be lower than the actual speed. Engineers often overcome this by using multi-antenna arrays or combining radar data with other sensors such as IMUs or LiDAR (Linpowave Robotics Applications).

Challenges in Industrial Speed Detection

While the theory is simple, real-world deployments introduce complexity. Below are the most common engineering hurdles:

-

Range–Doppler Coupling: In FMCW radars, range and velocity data overlap in the signal. Incorrect separation can lead to errors in both distance and speed estimation.

-

Ambiguities and Aliasing: Fast-moving targets can exceed the radar’s unambiguous velocity range, leading to misinterpreted speeds.

-

Multipath Reflections: Metallic environments, common in factories, create ghost signals that interfere with accurate Doppler readings.

-

Signal-to-Noise Ratio (SNR): Weak reflections from small or low-reflectivity objects make velocity estimates less reliable.

-

Temperature and Drift: Oscillator instability or thermal shifts can bias results unless compensated through calibration.

-

Multiple Moving Objects: Separating overlapping Doppler signals requires advanced algorithms and sometimes 4D radar systems (Springer on 4D Radar).

A detailed review of these challenges can be found in recent research on high-resolution mmWave sensing (MDPI Electronics, 2024).

Real-World Applications and Lessons Learned

Conveyor Belt Monitoring

Instead of relying on mechanical encoders that wear down, radar modules provide non-contact measurement of belt speed, reducing downtime and maintenance.

Autonomous Guided Vehicles (AGVs)

For AGVs in warehouses, wheel odometry often slips on smooth floors. mmWave radar adds a robust velocity reference, ensuring accurate navigation even under challenging conditions.

Industrial Robotics

Robots require precise feedback on both position and velocity to operate safely near humans. Linpowave customers have integrated radar into robotic platforms, combining obstacle detection with real-time speed monitoring to enhance both safety and productivity.

Traffic and Smart Infrastructure

Industrial-grade radar modules are also used in traffic speed monitoring, similar to radar guns, but adapted for 24/7 operation in outdoor environments.

These applications highlight that radar’s strength lies in its reliability where other sensors fail. Engineers in the Infineon Radar Community often share insights on mitigating multipath effects, calibrating sensors, and tuning chirp parameters for better Doppler resolution.

Looking Ahead: Where Is Industrial Radar Speed Detection Going?

The next generation of industrial radar is set to become smarter, more integrated, and more reliable. Key trends include:

-

4D Radar Technology: Adding elevation to range, azimuth, and velocity improves separation of multiple moving objects, a critical need in crowded factories.

-

AI-Powered Processing: Machine learning models are applied to filter clutter, compensate for multipath, and improve Doppler extraction (PMC Survey, 2024).

-

Integrated Radar SoCs: Radar-on-chip designs reduce cost and make adoption feasible even for small industrial systems.

-

Sensor Fusion: Combining radar with IMU, LiDAR, or camera data eliminates blind spots and improves reliability.

-

IIoT Integration: Radar sensors increasingly connect directly into factory networks, feeding speed data into predictive maintenance and real-time control systems.

The long-term vision is clear: radar speed detection will become as fundamental as temperature or pressure sensing in industrial automation.

Conclusion: What Should Engineers Take Away?

Industrial mmWave sensors are not simply replacements for optical or mechanical speed measurement—they open new possibilities for non-contact, accurate, and resilient velocity sensing in environments where other technologies break down.

To make the most of radar-based speed detection, engineers must remember:

-

Doppler measures radial velocity; geometry must be accounted for.

-

Accuracy is tied to SNR, multipath management, and calibration.

-

Advanced signal processing, including AI, is key to unlocking better performance.

-

Combining radar with other sensors produces more reliable outcomes in real deployments.

At Linpowave, we continue to develop radar products that meet these industrial challenges, enabling smarter, safer, and more efficient automation systems worldwide.

FAQ – Industrial mmWave Radar for Speed Detection

Q1: How does mmWave radar measure speed in industrial environments?

A1: mmWave radar measures speed using the Doppler effect, which detects frequency shifts in the reflected radar signal from moving objects. The shift is proportional to the radial velocity (toward or away from the sensor). FMCW radar modules calculate this shift digitally to provide real-time speed readings.

Q2: Can mmWave radar measure the speed of multiple objects simultaneously?

A2: Yes, modern radar modules with multi-antenna arrays or 4D radar capabilities can distinguish multiple moving objects. Advanced signal processing algorithms separate overlapping Doppler signals, even in cluttered industrial settings.

Q3: What factors affect the accuracy of radar speed detection?

A3: Key factors include: SNR, multipath reflections, radial velocity limitation, and temperature or oscillator drift. Calibration and signal processing help mitigate these effects.

Q4: How does radar compare to optical or mechanical speed sensors?

A4: Radar is non-contact, robust, and all-weather capable, making it ideal for harsh industrial conditions, unlike encoders or cameras that can be obstructed or wear out.

Q5: Can radar detect very slow or very fast movements accurately?

A5: Yes, but very slow movements may need longer integration time for precision, while very fast movements may require chirp adjustments to avoid aliasing.

Q6: How can I improve speed detection reliability in an industrial setup?

A6: Optimize placement, use multi-antenna systems, apply AI-based signal processing, fuse radar with IMU/LiDAR, and perform regular calibration.

Q7: Are mmWave radar modules compatible with smart factory systems?

A7: Yes. Modern mmWave modules support IIoT integration, enabling real-time speed monitoring, predictive maintenance, and automation control (Linpowave Robotics Applications).