Ultimate Guide to Millimeter Wave Radar: Integration, Applications, and Best Practices

Millimeter wave radar technology is transforming many industries by enabling precise, real-time sensing.Millimeter wave radar technology is transforming many industries by enabling precise, real-time sensing.Millimeter wave radar technology is transforming many industries by enabling precise, real-time sensing. This guide will show you how to use this powerful tool in applications such as automotive safety, industrial automation, and smart urban environments.This guide will show you how to use this powerful tool in applications such as automotive safety, industrial automation, and smart urban environments.This guide will show you how to use this powerful tool in applications such as automotive safety, industrial automation, and smart urban environments. Whether you're an engineer designing systems or a developer integrating sensors, understanding millimeter wave radar fundamentals and implementations is critical for innovation.Whether you're an engineer designing systems or a developer integrating sensors, understanding millimeter wave radar fundamentals and implementations is critical for innovation.Whether you're an engineer designing systems or a developer integrating sensors, understanding millimeter wave radar fundamentals and implementations is critical for innovation.

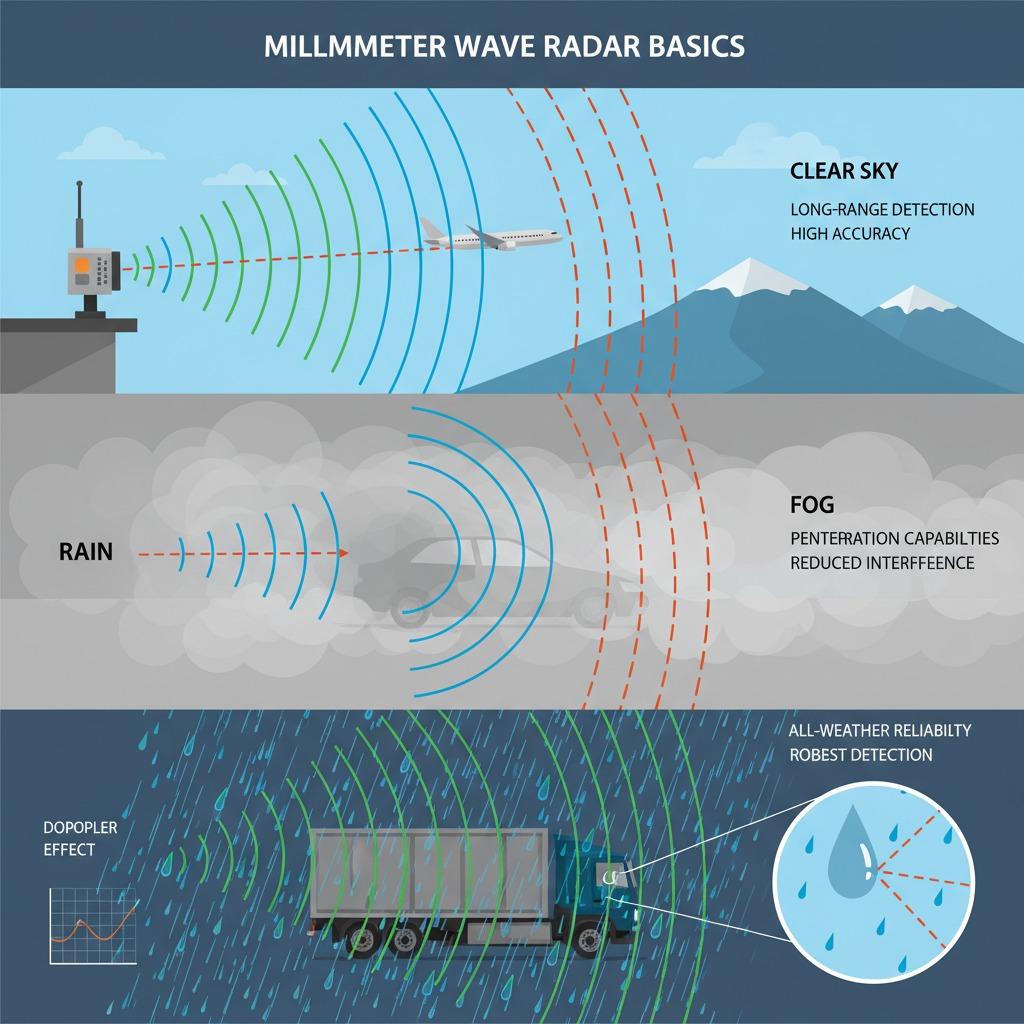

Understanding the Basics of Millimeter Wave Radar

To begin with Millimeter Wave Radar, understand its fundamental principles. It detects objects, measures distances, and tracks movements with high accuracy using electromagnetic waves with frequencies ranging from 30-300 GHz. Unlike traditional sensors, it can penetrate fog, dust, and rain, making it ideal for use in harsh environments. Begin by choosing a suitable frequency band, such as 77 GHz for automotive applications, and make sure your setup includes proper power management to preserve signal integrity. For beginners, use software tools such as MATLAB to simulate radar scenarios and visualize wave propagation prior to hardware deployment.

Implementing ADAS MMW Radar in Vehicles

When integrating ADAS MMW Radar into advanced driver assistance systems, take it one step at a time. First, choose a compact module that will fit neatly into the vehicle's bumpers or grilles. Our high-performance radar sensor, designed for autonomous driving, performs admirably here thanks to its robust construction and real-time data processing. Install it by adjusting the antenna alignment to maximize beam width and range (usually up to 200 meters). Next, connect it to the vehicle's ECU via CAN bus to enable collision avoidance and adaptive cruise control (ACC). To ensure accurate object detection, test under a wide range of conditions, including dynamic scenarios. This improves safety, even in inclement weather, paving the way for more efficient mobility.

Radar antenna design is crucial for millimeter wave radar efficiency. Start by defining requirements based on application—phased array antennas for beam steering in ADAS, or patch arrays for compact setups. Use simulation software to model radiation patterns and minimize sidelobes. Fabricate prototypes with materials like low-loss substrates to handle high frequencies. Tune for impedance matching to reduce signal loss, and incorporate shielding against interference. For industrial applications, ensure the design supports wide-angle scanning. This methodical process yields antennas that boost resolution and reliability in real-world deployments.

Leveraging Industrial Sensing with MMW Radar

Industrial sensing with MMW radar transforms manufacturing and logistics. Begin by identifying use cases, such as inventory tracking or machinery monitoring. Deploy a compact MMW radar module in harsh factory settings—its small footprint allows easy retrofitting. Configure sensors to detect metallic and non-metallic objects, integrating with PLC systems for automated responses. Perform initial calibration in controlled environments, then scale to full operations. Data from these radars enables predictive maintenance, reducing downtime. For best results, combine with edge computing to process signals on-site, ensuring low latency in automated assembly lines.

Mastering Millimeter Wave Radar Data Analysis

Millimeter Wave Radar Data Analysis unlocks actionable insights. After capturing raw signals, apply Fast Fourier Transform (FFT) to extract range and velocity information. Use algorithms like Constant False Alarm Rate (CFAR) for clutter suppression. Tools such as Python's SciPy library simplify processing—filter noise and classify targets based on Doppler shifts. Visualize results with heatmaps to identify patterns in traffic or robotic navigation. Regularly validate models against ground truth data to refine accuracy. This analysis is vital for applications from robotics to smart cities, turning raw radar feeds into intelligent decisions.

Deploying MMW Radar for Smart City and Robotics Applications

For MMW Radar for Smart City initiatives, map out infrastructure needs like traffic monitoring at intersections. Install low-profile sensors on poles, linking them to central networks via 5G. Calibrate for multi-target tracking to manage urban flow. In robotics, a millimeter wave radar for robotics enables obstacle avoidance in dynamic spaces. Mount compact units on drones or AGVs, programming pathfinding algorithms that fuse radar with IMU data. Conduct reliability testing to ensure operation in vibration and temperature extremes—our sensor's embedded software shines in such tests. This setup fosters safer, more efficient urban and robotic ecosystems.

Ensuring Reliability and Cost-Effectiveness

Reliability testing of millimeter wave radar involves environmental simulations: exposing units to humidity, vibrations, and EMI per standards like ISO 16750. Iterate designs based on failure modes to achieve MTBF over 10,000 hours. For budget-conscious projects, opt for a low-cost MMW radar solution without sacrificing performance—leverage integrated chips for affordability. Source components wisely and scale production to lower per-unit costs. By following these steps, you balance innovation with practicality, making millimeter wave radar accessible for widespread adoption in ADAS, industry, and beyond.